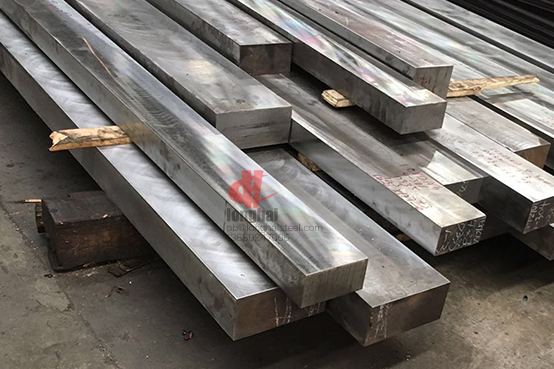

PH13-8Mo锻造扁钢

产品参数

- 冶炼方式: VIM+ESR

- 执行标准: UNS 、AMS 、

- 产品尺寸: 128*270*601mm

- 交货状态: 锻造 、固溶 、时效 、

- 表面状态: 铣削 、

- 库存状态: 查看库存

产品详情

PH13-8Mo stainless steel is a martensitic precipitation/age-hardening stainless steel capable of high strength and hardness along with good levels of resistance to both general corrosion and stress-corrosion cracking. In addition, the alloy exhibits good ductility and toughness in large sections in both the longitudinal and transverse directions. The excellent properties of PH13-8Mo stainless steel are obtained through close control of chemical composition and microstructure plus specialized melting which reduces impurities and minimizes segregation. Compared to other ferrous-based materials, this alloy offers a high level of useful mechanical properties under severe environmental conditions. PH13-8Mo stainless steel has good fabrication characteristics and can be age-hardened by a single low temperature treatment. Cold work prior to aging increases the aging, especially for lower aging tempratures. PH13-8Mo stainless steel has been used for valve parts, fittings, cold-headed and machined fasteners, shafts, landing gear parts, pins, lockwashers, aircraft components, nuclear reactor components and petrochemical applications requiring resistance to stress-corrosion cracking. Generally, this alloy should be considered where high strength, toughness, corrosion resistance, and resistance to stress-corrosion cracking are required in a steel showing minimal directionality in properties.

PH13-8Mo stainless steel has displayed excellent resistance to oxidation up to approximately 1100°F. Long-term exposure to temperatures between about 600-900°F (288-482°C) can result in reduced toughness in precipitation hardenable stainless steels. The reduction in toughness can be minimized in some cases by using higher aging temperatures. Short exposures to elevated temperatures can be considered, provided the maximum temperature is at least 50°F (28°C) less than the aging temperature.

Heat Treatment PH13-8Mo stainless steel is hardened by heating solution-treated material, Condition A, to a temperature of 950°F to 1150°F for 4 hours, then air cooling. The various heat treatments are as follows (note all times are "at temperature"): Condition A(Solution treated or Annealed) Heat at 1700°F +/-15°F (time dependent on section size), cool to below 60°F so that the material is completely transformed to martensite. Normally, 1 hour hold at temperature is suggested. Section under 36 sq. inches can be quenched in a suitable liquid quenchant; larger sections should be air cooled. Condition RH 950 (Precipitation or Age Hardened) Cold treat solution treated material to -100°F for 2 hours minimum. Air warm to room temperature. This must be done within 24 hours after solution treatment. Heat cold-treated material to 950°F +/-10°F for 4 hrs. Air cool. Condition H 950, H 1000, H 1050, H 1100, H 1150 (Precipitation or Age Hardened) Heat solution-treated material at specified temperature +/-10°F for 4 hrs. Air cool. Condition H 1159M(Precipitation or Age Hardened) Heat solution-treated material at 1400°F +/-10°F for 2 hrs. Air cool; then treat at 1150°F +/-10°F for 4 hrs. Air cool. Heat Treating After Overaging PH13-8Mo stainless steel in the H 1150 and H 1150M overaged conditions will not respond to further aging treatments. Therefore, if the alloy is obtained in either condition (for forging, optimum cold heading and machining) it must be solution treated at 1700°F, after these operations and before subsequent aging. It should be kept in mind that the hardness for the H 1150 condition falls within the hardness range for the solution-treated condition; therefore, hardness cannot be used to distinguish between the H 1150 and solution-treated conditions. Size Change Upon Aging Upon aging a predictable size change will occur for PH13-8Mo stainless steel. Increasing amounts of contraction occur as aging temperature is increased.